Choosing the right sheet metal supply is crucial for the success of any project, whether in construction, manufacturing, or custom fabrication. According to a market research report by Smithers Pira, the global sheet metal market is expected to reach approximately $250 billion by 2025, driven largely by innovations in technology and materials. As industries increasingly demand precision and sustainability, selecting the right supplier becomes essential to meet project specifications and quality standards.

The sheet metal supply landscape is diverse and ever-evolving, characterized by a wide range of materials, thicknesses, and finishes. A recent analysis from IBISWorld highlighted that the sheet metal fabrication industry, valued at approximately $19 billion in the U.S., is seeing steady growth, indicating a robust demand for quality materials. Companies are not only looking for competitive pricing but also emphasizing the importance of supplier reliability and the ability to offer tailored solutions to specific project needs. Understanding these dynamics and identifying the right sheet metal supply provider can significantly impact the overall efficiency and effectiveness of your project outcomes.

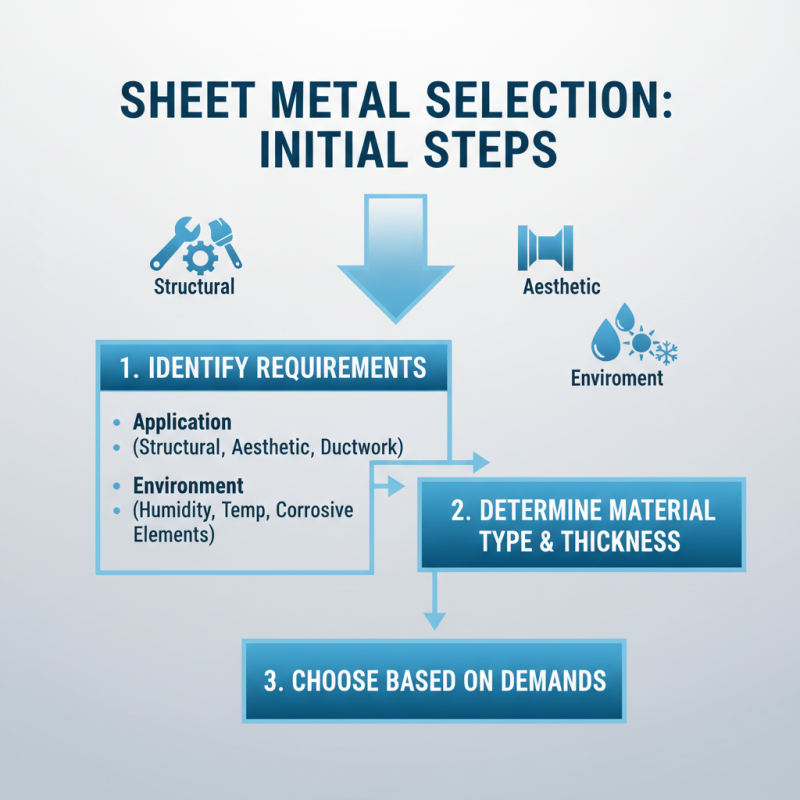

When selecting the appropriate sheet metal for your project, the first step is to clearly identify your requirements. Start by considering the specific application of the sheet metal. Will it be used for structural support, aesthetic purposes, or perhaps for creating ductwork? Each application has distinct demands, which will influence the type and thickness of the material you will need. Additionally, think about the environment the finished product will be exposed to, as factors such as humidity, temperature variations, and corrosive elements can affect your choice.

Next, you should assess the mechanical properties you require from the sheet metal. Consider aspects such as tensile strength, ductility, and formability. If your project involves complex shapes or deep draws, choosing a metal with good formability will be essential. Similarly, if strength is a priority, opting for a higher tensile strength material is crucial. Lastly, don't forget to think about weight considerations, especially if the final assembly will need to be lightweight or easily transportable. By thoroughly understanding your project requirements in these areas, you can make an informed decision when selecting the right sheet metal supply for your needs.

When selecting the right sheet metal for your project, it's crucial to understand the various types of materials available, each offering distinct properties and applications. Common types of sheet metal include aluminum, stainless steel, and galvanized steel. Aluminum is lightweight, corrosion-resistant, and highly malleable, making it an excellent choice for applications that require ease of fabrication and transport, such as in the automotive and aerospace industries. Its non-rusting nature also makes it suitable for outdoor projects.

Stainless steel, on the other hand, is renowned for its strength and resistance to heat and corrosion. This makes it ideal for environments exposed to moisture or chemicals, like kitchens and laboratories. Its durability ensures long-lasting performance, though it may require more specialized tooling and techniques during fabrication. Lastly, galvanized steel, coated with a layer of zinc to prevent rusting, is often used in construction and HVAC systems. Its balance of cost-effectiveness and protective qualities makes it a popular choice for structural applications where exposure to the elements is a concern.

Understanding the specific requirements of your project, such as weight restrictions, environmental conditions, and aesthetic considerations, will help you make an informed decision on the most suitable sheet metal material. By assessing these properties, you can ensure that you select a material that aligns with your project goals, enhancing both functionality and longevity.

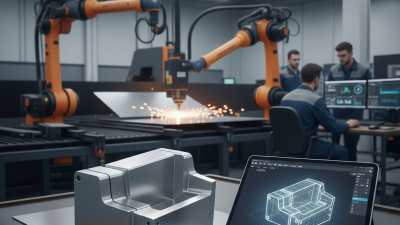

When evaluating sheet metal suppliers, one of the foremost aspects to consider is the quality of their materials. High-quality sheet metal is essential for ensuring the durability and functionality of your final product. Suppliers should be able to provide detailed specifications and certifications to demonstrate that their materials meet industry standards. It’s advisable to request samples before making significant purchases, allowing you to assess the material's thickness, finish, and overall performance characteristics in your specific application.

Reliability is another critical factor in choosing a supplier. This encompasses not only their ability to deliver materials promptly but also the consistency of their product offerings. A reliable supplier will have a proven track record of meeting deadlines and fulfilling orders accurately. Researching customer reviews and testimonials can provide insights into a supplier's reliability. Additionally, effective communication is vital; a good supplier should be responsive to inquiries and concerns, ensuring a smooth collaboration throughout your project's duration.

Lastly, a supplier's reputation within the industry cannot be overlooked. A company that is well-regarded by its clients often indicates a commitment to excellence and customer satisfaction. Checking for industry awards, certifications, and participation in professional organizations can also shed light on a supplier’s standing in the market. By focusing on these key areas—quality, reliability, and reputation—you can make a more informed decision that aligns with your project needs.

When selecting a sheet metal supply for your project, understanding the pricing structures and cost factors is crucial. The cost of sheet metal can vary significantly based on several elements, including material type, thickness, and finish. For example, aluminum may cost more upfront than steel, but its lightweight nature can save on shipping costs and ease of handling, ultimately affecting the total expenditure. Additionally, specialized finishes, such as powder coating or anodizing, can add to the material's price, so it’s essential to evaluate how these factors fit your budget and project objectives.

Tips: Always request a detailed quote that breaks down the costs associated with materials, processing, and finishing. This not only aids in comparison shopping but also helps to avoid unexpected expenses down the line. It's also advisable to consider bulk purchasing options, as many suppliers offer discounts on larger orders, which can further optimize your project budget.

Conversely, be aware of hidden costs that may arise during the fabrication or transportation of your materials. Factors such as lead times and delivery charges can impact the final price. Ensure that your chosen supplier provides transparent communication about their pricing policies, as this will allow for better financial planning and project execution.

Effective communication with sheet metal suppliers is crucial for meeting your project needs and ensuring quality outcomes. According to a recent report by the Fabricators & Manufacturers Association, a staggering 70% of project delays are attributed to miscommunication between contractors and suppliers. Therefore, setting clear expectations and specifications from the outset can significantly mitigate risks. Be specific about your project requirements, such as the type of metal, thickness, and finish needed, thus enabling suppliers to provide accurate quotes and timelines.

Additionally, establishing a proactive line of communication throughout the project lifecycle is essential. Frequent check-ins can help address any issues that arise early, reducing the potential for costly mistakes. A survey conducted by the American Metal Market indicated that companies that maintain regular communication with their suppliers report a 30% improvement in project efficiency. Utilize tools such as detailed emails, project management software, or collaboration platforms to keep everyone on the same page. This approach not only improves transparency but also builds a strong working relationship with your suppliers, which is vital for long-term success in your projects.

| Dimension | Material Type | Gauge Thickness | Finish Type | Quantity Needed |

|---|---|---|---|---|

| 48" x 96" | Aluminum | 0.040" | Anodized | 100 Sheets |

| 36" x 120" | Steel | 0.050" | Galvanized | 200 Sheets |

| 24" x 48" | Stainless Steel | 0.030" | Brushed | 150 Sheets |

| 60" x 120" | Copper | 0.062" | Natural | 50 Sheets |

| 20" x 30" | Brass | 0.010" | Polished | 300 Sheets |

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close