Aluminum die casting is increasingly gaining traction as one of the most efficient manufacturing processes in various industries, thanks to its ability to produce complex geometries with minimal waste. With projected growth rates of around 6.5% annually, the die casting industry is expected to reach a market value of approximately $10 billion by 2025, according to a recent report by Grand View Research. This growth presents a significant opportunity for beginners in the field to leverage advanced aluminum die casting techniques to enhance production quality and efficiency.

Renowned industry expert Dr. Michael Williams emphasizes the importance of mastering the fundamental principles of aluminum die casting. He states, "Understanding the critical factors of aluminum die casting not only improves part quality but also reduces production costs." For beginners, grasping these essential tips can be the key to unlocking the potential of aluminum die casting and ensuring a successful entry into this dynamic field. As the industry continues to evolve, staying informed and adopting best practices will empower newcomers to contribute effectively to the manufacturing landscape.

Aluminum die casting is a crucial process in manufacturing, particularly favored for its ability to produce complex shapes with high precision and smooth surfaces. This method involves injecting molten aluminum into a mold under high pressure, which ensures rapid production rates and reduced waste. According to a report by the Aluminum Association, the global aluminum die casting market is expected to reach approximately $7.5 billion by 2025, driven by increased demand in sectors such as automotive, aerospace, and consumer electronics. Understanding these fundamentals is vital for beginners aiming to succeed in this field.

For those new to aluminum die casting, it's essential to grasp several key principles. First, the choice of alloy significantly affects the final product's properties, including its strength, ductility, and corrosion resistance. Typically, alloys like A380 and A383 are preferred for their excellent fluidity and mechanical performance. Additionally, beginners should pay attention to the cooling rate of the mold, as it impacts the casting's dimensional accuracy and surface finish. Industry reports highlight that optimizing cooling times can lead to reductions in cycle times by up to 20%. Familiarizing oneself with these basics will provide a solid foundation for further exploration into the techniques and advancements within aluminum die casting.

When venturing into the world of aluminum die casting, having the right equipment and tools is crucial for achieving precise and high-quality results. Essential tools include a die casting machine, which applies pressure to force molten aluminum into the die, ensuring a perfect fit with minimal imperfections. Alongside this, a reliable melting furnace is necessary for heating aluminum to its liquid state, allowing for the smooth flow into molds. Moreover, auxiliary tools like thermocouples and temperature controllers are vital for maintaining optimal casting temperatures, which can significantly affect the properties of the final product.

Additionally, beginners should focus on selecting the right dies for their projects. The die must be properly designed and maintained to ensure longevity and repeatability of casting cycles. Investing in quality die materials will also help in reducing defects and improving overall production efficiency. To further enhance outcomes, it’s recommended to familiarize yourself with proper mold release agents that can aid in easy ejection of the final cast part while preventing mold damage.

Another critical tip is to prioritize safety by incorporating essential safety equipment such as heat-resistant gloves, protective eyewear, and fire-resistant clothing. Proper ventilation is also important to mitigate risks from fumes when melting aluminum. By equipping yourself with the right tools and prioritizing safety, you can establish a solid foundation for successful aluminum die casting practices.

| Tip | Description | Key Equipment/Tool |

|---|---|---|

| 1. Understand Material Properties | Familiarize yourself with the characteristics of aluminum alloys used in die casting. | Material Data Sheets |

| 2. Invest in Quality Molds | High-quality molds produce accurate and consistent parts. | Metal Molds |

| 3. Control Melting Temperature | Ensure aluminum is melted at the correct temperature for optimal flow and strength. | Melting Furnace |

| 4. Maintain Proper Injection Speed | Adjust injection speed to minimize air entrapment and achieve uniform filling. | Die Casting Machine |

| 5. Optimize Cooling Time | Proper cooling time affects the mechanical properties of the casted part. | Cooling System |

| 6. Implement Quality Checks | Set up inspections to ensure the parts meet specifications and standards. | Quality Control Tools |

| 7. Ensure Safety Protocols | Follow safety procedures to protect personnel from hazards. | Protective Gear |

| 8. Properly Maintain Equipment | Routine maintenance minimizes downtime and improves efficiency. | Maintenance Tools |

| 9. Train Your Team | On-going training ensures your team is up-to-date with best practices. | Training Programs |

| 10. Analyze and Optimize Processes | Regular analysis of the casting process can help identify areas for improvement. | Data Analysis Software |

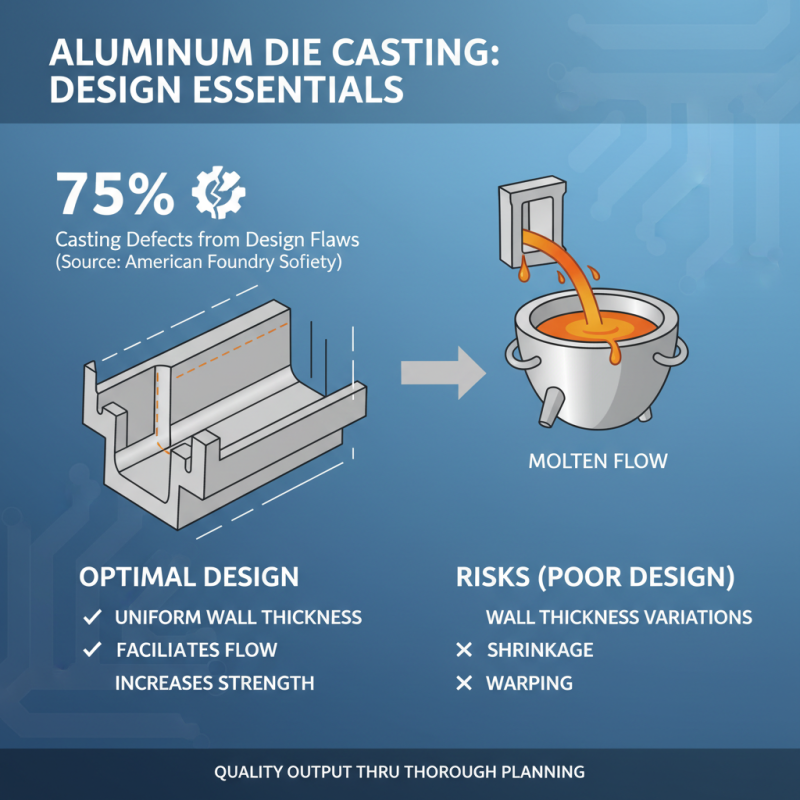

When considering aluminum die casting, essential design considerations play a crucial role in achieving high-quality output. The geometry of the part being cast is paramount; intricate designs can greatly influence the success of the casting process. According to a report by the American Foundry Society, approximately 75% of casting defects stem from design flaws, emphasizing the need for thorough planning. Effective design should factor in wall thickness uniformity, as variations can lead to issues such as shrinkage and warping, which ultimately affect the final product's integrity. A uniform wall thickness not only facilitates better flow of molten aluminum but also enhances mechanical strength post-casting.

Another critical aspect of design considerations revolves around tolerances and allowances. Industry standards suggest that die casting tolerances can range from ±0.005 to ±0.020 inches depending on the complexity of the part and the casting method employed. It’s vital for designers to closely assess the specifications needed for the final application. Additionally, the incorporation of proper draft angles is essential to ensure easy removal of the cast from the dies, which can significantly reduce the risk of surface damage or casting defects. According to a study conducted by the National Institute of Standards and Technology, the correct draft angle can improve the manufacturing yield by up to 30%, underscoring its importance in the die casting design process. These considerations, if implemented diligently, can lead to substantial improvements in production efficiency and product quality.

When embarking on your first aluminum die casting project, it's crucial to avoid common pitfalls that can lead to disappointing results. One significant mistake is not adequately preparing the die. Neglecting to clean and apply appropriate release agents can hinder the demolding process, resulting in defects or damage to the cast parts. Additionally, ensuring that the die is properly aligned can prevent issues such as miscasting or uneven surfaces. Take time to inspect and maintain your equipment before starting the casting process.

Another area where beginners often stumble is in managing temperatures during the casting process. Aluminum has specific temperature requirements for optimal fluidity and mold filling. Failing to reach or maintain the correct pouring temperature can lead to cold shuts or incomplete filling, compromising the integrity of the cast piece. Furthermore, it's essential to control the cooling rate after pouring, as rapid cooling can cause cracking or warping. By paying attention to these temperature factors and conducting thorough pre-project checks, you can significantly enhance your chances of a successful aluminum die casting experience.

Quality control in aluminum die casting is essential to ensure the production of high-quality components that meet industry standards. According to a report by Grand View Research, the global aluminum die casting market is projected to reach USD 16.54 billion by 2025, emphasizing the growing demand for precision-engineered parts. Implementing best practices in quality control can significantly reduce defects and minimize waste, thereby enhancing productivity and profitability.

One effective practice is to conduct thorough material analysis before the casting process. Understanding the alloy composition and properties of aluminum is crucial, as impurities can lead to structural weaknesses in the final product. Routine monitoring of melting temperatures and metal fluidity can help maintain optimal casting conditions. Regular check-ups on die wear and tear also play a pivotal role in quality assurance, as worn dies can increase production inaccuracies.

Tips for maintaining quality control include establishing a robust inspection regime that employs non-destructive testing methods to assess the integrity of cast components without damaging them. Another useful tip is to implement process adjustments based on real-time data analytics, as suggested by a recent survey from the Aluminum Association. This approach allows manufacturers to identify and rectify potential issues swiftly, ensuring consistent quality throughout the casting cycle. By focusing on these best practices, beginners in aluminum die casting can maximize efficiency while minimizing defects.

This chart illustrates key quality metrics in aluminum die casting processes that every beginner should monitor to ensure optimal results.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close