Sheet metal work is both an art and a science. It involves shaping, cutting, and joining metal sheets to create various products. Beginners often find it challenging, while professionals continue to refine their skills. Mastering the techniques of sheet metal work is vital for anyone aiming to excel in this craft.

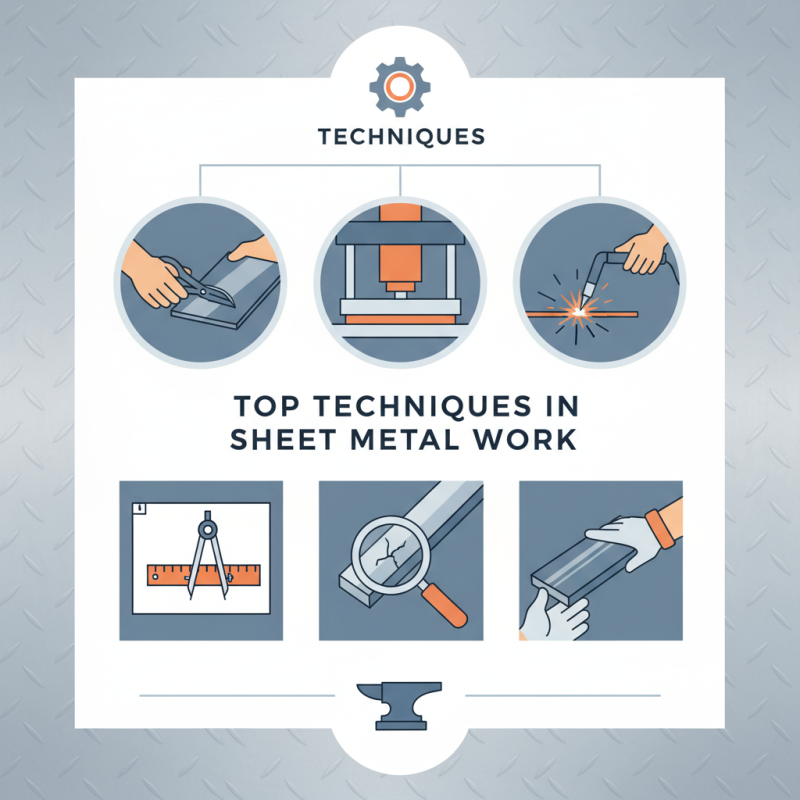

Various methods exist in this field. Techniques like cutting, bending, and welding are essential. Understanding each technique is crucial. Mistakes can happen often, especially when starting out. Learning from these errors is part of the journey.

Every project presents unique challenges, whether it’s precision measurements or understanding weld types. Sheet metal work requires continuous learning. Embracing imperfections, seeking improvement, and practicing regularly can lead to success. This craft demands patience and dedication.

Understanding sheet metal properties is crucial for both beginners and professionals. The thickness of sheet metal significantly influences its application and performance. Common thicknesses range from 0.4 mm to 6 mm. For instance, automotive applications often require thinner sheets, while architectural projects might use thicker materials. The American Iron and Steel Institute categorizes sheet metal into various gauges, highlighting their respective characteristics.

Material types are another essential factor. Steel, aluminum, and copper are popular choices, each offering distinct advantages. Aluminum, known for its lightweight properties, is ideal for aerospace applications. Meanwhile, steel is favored for its strength and durability. According to industry reports, the global sheet metal market is expected to grow by 2.5% annually, driven by rising demand in the construction sector. However, many newcomers struggle with understanding the right material for their specific needs, leading to inefficient designs.

Applications of sheet metal vary widely, including automotive, construction, and electronics. Each field has unique requirements. In electronics, for example, precision is vital. Many beginners overlook the importance of tolerances and fit. This can result in significant revisions and wasted materials. Professionals often spend years refining their techniques, learning from mistakes, and adapting to new challenges in material sciences. Understanding these properties creates a foundation for successful sheet metal work.

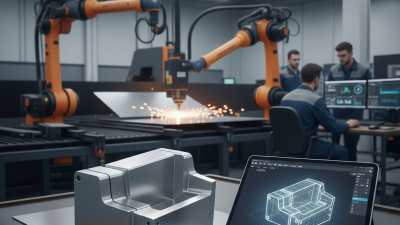

Sheet metal fabrication requires essential tools and equipment. Beginners need to start with basic items. A good set of shears is vital for cutting sheet metal accurately. They come in various sizes and types, making them versatile for different tasks. A bending brake is another critical tool. It allows users to create sharp bends and folds with precision.

Clamps and a sturdy workbench are also important for any project. You can secure your materials easily, preventing accidents. Safety gear is non-negotiable. Gloves, goggles, and ear protection keep you safe while working. Often, novice fabricators overlook this, leading to minor injuries or discomfort.

Welding equipment is essential for joining pieces together. Gas-powered or electric welders offer different advantages. Each has a learning curve, and that can be frustrating. Mistakes are part of the journey. As you practice, you’ll discover what works best. Trial and error help refine your technique. Embrace the process; it’s all about improvement.

Sheet metal work is an essential skill for many industries. Understanding cutting, bending, and forming methods can elevate one's craftsmanship. Cutting is often the first step. It requires precision and the right tools. According to industry reports, improper cutting techniques can lead to a 30% increase in material waste. Ensuring sharp tools and steady hands is vital.

Bending techniques come next. This process shapes metal by applying force. It can be tricky. A small mistake can lead to angles that are off by several degrees. This is often overlooked. Many beginners underestimate the necessity of accurate measurements. A simple tip: always measure twice before cutting or bending.

Forming methods are the final stage. Techniques like deep drawing and stretching create complex shapes. These methods require practice and patience. Reports indicate that mastery in forming can reduce production times by 15%. Learning from failures is crucial. Making small adjustments after errors can lead to significant improvements. Remember, every expert was once a beginner. Focus on mastering each step, and don’t hesitate to seek feedback.

| Technique | Description | Skill Level | Common Tools |

|---|---|---|---|

| Cutting | Process of removing material from a sheet to obtain desired shape and size. | Beginner | Shears, Laser Cutters, Plasma Cutters |

| Bending | Buckling the sheet metal to create angles or curves. | Intermediate | Brake Press, Hand Benders |

| Forming | Molding the sheet metal into specific shapes using dies and tools. | Advanced | Punch Press, Roll Forming Machines |

| Welding | Joining two pieces of metal together through melting and fusing. | Intermediate | MIG Welder, TIG Welder |

| Finishing | Applying surface treatments for corrosion resistance and aesthetics. | Beginner | Sanders, Polishers, Coating Sprayers |

Welding is a crucial technique in sheet metal work. It involves joining metal pieces using high heat. For beginners, start with MIG welding. It's easier to handle than other methods.

Tip: Always wear proper safety gear. Gloves and helmets are essential. Check your equipment regularly to avoid mishaps.

Punching is another essential skill. It creates holes in metal sheets for various uses. Professionals use hydraulic punches for efficiency. Beginners can start with manual tools.

Tip: Practice on scrap metal first. This helps build confidence before dealing with quality material. Pay attention to precision; mistakes can be costly.

Pressing shapes the metal into desired designs. It's often used for making automotive parts. Understanding pressure settings is vital for professionals. Incorrect settings can ruin your work.

Tip: Keep an eye on the metal's temperature. Too much heat can cause distortion. It's important to be patient and allow the metal to cool. Mastery takes time and practice.

This bar chart displays various sheet metal work techniques used by both beginners and professionals, highlighting the popularity and effectiveness of each method.

Safety is paramount in sheet metal work. Workers must wear appropriate personal protective equipment (PPE), including gloves and goggles. Sharp edges can easily cause injuries. Always inspect tools before use. Damaged equipment can lead to accidents. Training sessions on safety standards should be regular. It’s essential for both beginners and professionals.

Tips: Keep your work area clean. Clutter can lead to slips and falls. Store tools properly. Make sure they are accessible yet out of the way. Communicate clearly with team members about safety protocols. Set a mantra: “Safety first, always.” This can reinforce the importance of vigilance.

Even experienced workers may overlook safety protocols. Regularly reviewing procedures can uncover gaps. Are you comfortable using tools? If not, seek help. It’s okay to admit uncertainty. Learning never stops in this field. Safety practices ensure that everyone returns home unharmed.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close