Sheet metal parts play an integral role in a wide array of industries, from automotive to aerospace, construction to electronics. Understanding the essential features and applications of these components is crucial for anyone involved in manufacturing or product design. Sheet metal fabrication involves the process of shaping and cutting metal sheets into functional parts that meet specific design requirements. This versatility allows for the creation of a wide range of products, from simple brackets to intricate enclosures.

The key attributes of sheet metal parts include their strength, lightweight nature, and ease of fabrication, which makes them an ideal choice for various applications. These parts are often used for structural support, housings, and various functional components, enabling manufacturers to achieve high performance while maintaining cost-effectiveness. As technology advances, the production of sheet metal parts continues to evolve, incorporating innovative techniques and materials that enhance durability and functionality. In this article, we will explore the essential features and applications of top sheet metal parts, providing valuable insights for those looking to leverage their benefits in their projects.

When assessing the quality of sheet metal parts, several key characteristics come to the forefront. First and foremost is material selection, which plays a significant role in durability and performance. According to a study by the Sheet Metal and Air Conditioning Contractors' National Association, around 70% of sheet metal failures can be traced back to inadequate material properties. High-quality metals such as stainless steel and aluminum alloys are often preferred for their resistance to corrosion and strength-to-weight ratio.

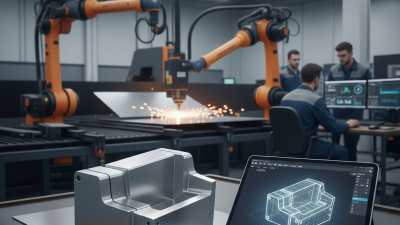

Another important characteristic is the manufacturing process, which directly influences the final product's quality. Precision machining techniques, such as laser cutting and CNC bending, ensure that parts meet stringent tolerances and specifications. Research by the Fabricators & Manufacturers Association highlights that using advanced technologies can improve precision by up to 40%, drastically reducing the likelihood of errors and material waste.

Tips: When selecting sheet metal parts, always verify the certifications of the manufacturing processes involved. Look for ISO 9001 certifications as a mark of quality assurance. Additionally, request detailed specifications related to tolerances and surface finishes to ensure the parts will perform optimally in their intended applications.

Sheet metal parts play a crucial role across a multitude of industries due to their versatility and adaptability. In the automotive sector, for instance, sheet metal is extensively used for manufacturing body panels, chassis components, and brackets. The lightweight yet durable nature of sheet metal enhances fuel efficiency while maintaining structural integrity. Additionally, it allows for complex shapes and designs that are essential for modern vehicle aesthetics and functionality, proving essential for both safety and performance.

In the electronics industry, sheet metal parts are utilized to create enclosures and chassis for electronic devices. This ensures not only protection from environmental factors but also electromagnetic interference shielding, which is vital for sensitive electronic components. Furthermore, in the construction sector, sheet metal is employed for roofing, HVAC systems, and decorative fixtures, contributing to both the functionality and aesthetics of buildings. Its resistance to corrosion and ability to withstand harsh conditions make it an ideal choice for both indoor and outdoor applications, highlighting its significance in a wide array of industrial contexts.

When it comes to manufacturing sheet metal parts, the choice of materials plays a crucial role in determining the quality and functionality of the final product. Common materials include stainless steel, aluminum, carbon steel, and brass, each offering unique properties that cater to specific applications. For instance, stainless steel is known for its corrosion resistance, making it ideal for environments exposed to moisture, while aluminum is lightweight and has excellent conductivity, making it suitable for electrical components.

Tips: When selecting materials for sheet metal parts, consider the environmental conditions they will face. For outdoor applications, materials with high corrosion resistance may be necessary, while for high-stress environments, tougher alloys may be more appropriate.

Another important aspect is the thickness of the metal sheet, as it can significantly impact durability and manufacturability. Thicker sheets are generally stronger, but they may also require more intensive machining processes. Understanding the requirements of the intended application can guide you in making the right choices.

Tips: Always consult with material specialists to ensure you select the right thickness and type of metal for your project. This can save costs and improve the overall performance of the finished part.

This bar chart illustrates the percentage distribution of various materials commonly used in the production of sheet metal parts. Understanding these materials is crucial for making informed decisions in design and manufacturing processes.

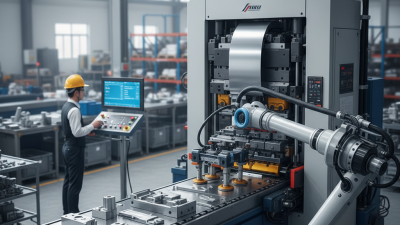

The manufacturing process of sheet metal parts encompasses various techniques and technologies essential for producing high-quality components. One of the most prominent methods is metal forming, which includes processes like bending, shearing, and punching. These techniques allow manufacturers to manipulate metal sheets into desired shapes without compromising structural integrity. Precise machinery, such as CNC (Computer Numerical Control) machines, plays a critical role in achieving high accuracy and repeatability during these processes.

Another important aspect of sheet metal fabrication is the joining techniques, such as welding, riveting, and adhesive bonding. Each method has unique advantages, depending on the application and the materials used. For instance, welding provides strong, permanent connections ideal for heavy-duty applications, while riveting is often used in industries where disassembly is advantageous. Furthermore, advancements in technologies like laser cutting and water jet cutting have revolutionized the way sheet metal parts are produced, allowing for intricate designs and reducing waste during the fabrication process. These methodologies not only enhance the functionality of the final products but also significantly improve efficiency in manufacturing operations.

The landscape of sheet metal part design and production is undergoing transformative changes driven by advancements in technology and shifting industry demands. One significant trend is the increasing adoption of automation and robotics in manufacturing processes. According to a report by the International Federation of Robotics, global sales of industrial robots are expected to reach 400,000 units annually by 2024, which will enhance precision and reduce labor costs in sheet metal production. This shift allows manufacturers to respond more rapidly to market changes and customize products at scale, fostering greater flexibility in design.

Another key trend is the integration of additive manufacturing and advanced software solutions, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies enable designers to create more complex geometries and optimize material usage, minimizing waste while maintaining structural integrity. A study from the Sheet Metal Industries Association highlights that companies utilizing these methods report a 30-40% increase in efficiency compared to traditional techniques. Furthermore, the focus on sustainability is compelling manufacturers to explore eco-friendly materials and processes, aligning with broader environmental goals while meeting the demands of increasingly conscious consumers.

Another key trend is the integration of additive manufacturing and advanced software solutions, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies enable designers to create more complex geometries and optimize material usage, minimizing waste while maintaining structural integrity. A study from the Sheet Metal Industries Association highlights that companies utilizing these methods report a 30-40% increase in efficiency compared to traditional techniques. Furthermore, the focus on sustainability is compelling manufacturers to explore eco-friendly materials and processes, aligning with broader environmental goals while meeting the demands of increasingly conscious consumers.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close