In today's rapidly evolving construction and manufacturing landscape, finding the right sheet metal supply services is crucial for ensuring the integrity and efficiency of your projects. According to a recent industry report by the Metal Industries Association, the sheet metal supply market in North America has witnessed a remarkable growth of 5.6% annually over the past five years, underscoring the increasing demand for quality materials and reliable suppliers. As businesses strive to maintain competitive edges, selecting the appropriate sheet metal supplier can significantly influence overall project outcomes, cost management, and timelines.

Industry expert John Carter, a lead analyst at Metal Insights, emphasizes the importance of making an informed choice in this sector: "Choosing the right sheet metal supply service is not just about cost; it's about finding a partner who understands your specific needs and can deliver quality consistently." This insight highlights the necessity for companies to assess potential suppliers carefully, taking into account factors such as material quality, service reliability, and customization options. With the right approach, businesses can establish strong partnerships that not only meet their current requirements but also adapt to future demands within their operations.

When seeking the best sheet metal supply services, a comprehensive assessment of your specific needs is paramount. Understanding the types of materials required, such as aluminum, stainless steel, or galvanized steel, forms the foundation of this evaluation. According to the Fabricators and Manufacturers Association (FMA), approximately 30% of manufacturing companies report difficulties in sourcing high-quality sheet metal due to varying grades and specifications. Therefore, identifying your project specifications, including thickness, finish, and tolerance requirements, will streamline the selection process.

In addition to material considerations, discerning the volume and frequency of your sheet metal needs is critical. A report by the American Metal Market indicates that 62% of businesses observed fluctuations in demand over the past five years, highlighting the need for flexibility in supply chain arrangements. Establishing a clear understanding of your production cycles can assist in determining whether you need a local supplier for just-in-time deliveries or a vendor capable of handling larger-scale orders. By evaluating these parameters, you can effectively pinpoint the right supplier who can best support your operational goals while ensuring quality and reliability in the materials supplied.

| Tip No. | Tip Description | Considerations | Location |

|---|---|---|---|

| 1 | Assess Your Specific Needs | Thickness, type, and finish of sheet metal required. | Local vs. regional suppliers |

| 2 | Check Supplier Certifications | Look for ISO certifications or industry standards compliance. | Nearby accredited suppliers |

| 3 | Evaluate Delivery Options | Timeliness and flexibility of delivery schedules. | Proximity to your operations |

| 4 | Compare Pricing Structures | Look for transparent pricing based on project requirements. | Local pricing variations |

| 5 | Read Customer Reviews | Assess quality of service and material based on feedback. | Online platforms and forums |

| 6 | Inquire About Customization Options | Ability to provide tailored solutions based on your specifications. | Supporting local fabricators |

| 7 | Confirm Stock Availability | Ensure the supplier can meet your order volume without delays. | Inventory location |

| 8 | Visit the Facility | Tour the supplier's facility to assess capabilities and equipment. | Local visits |

| 9 | Check After-Sales Support | Understand their policy on returns and support for handling issues. | Customer service proximity |

| 10 | Seek Referrals and Recommendations | Ask industry peers for reliable suppliers they use. | Network locally |

When evaluating local sheet metal suppliers, it is crucial to consider several key metrics to ensure you partner with a reliable provider. First, assess the supplier’s experience and reputation in the industry. A company that has been in business for several years likely has established itself through quality service and satisfied customers. Look for online reviews and testimonials to gauge customer satisfaction and trustworthiness.

Another important metric is the range of products and services offered. A versatile supplier who can provide various types of metals, finishes, and fabrication options will be more beneficial for your projects. This flexibility can save you time and effort, as you won’t have to seek multiple vendors to meet your specific needs.

Tip: Always request quotes from multiple suppliers to compare pricing and services. This practice not only helps you understand the market rates but also helps identify suppliers who offer the best value for your money. Additionally, don’t hesitate to ask about their turnaround times and delivery options, as timely service can be a game changer for your project deadlines.

This bar chart represents key metrics to consider when evaluating local sheet metal suppliers, including Pricing, Quality, Delivery Time, Customer Service, and Range of Products. Evaluate these factors to find the best supplier for your needs.

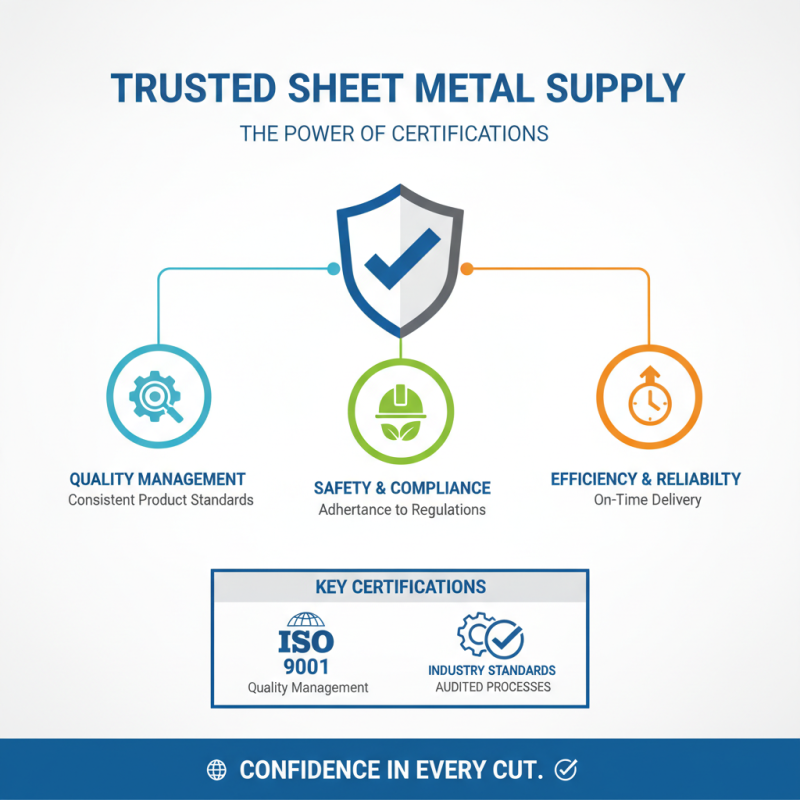

When searching for reliable sheet metal supply services, the importance of certifications cannot be overstated. Certifications serve as a testament to a supplier's quality management systems and their adherence to industry standards. Suppliers who have achieved recognized certifications demonstrate their commitment to maintaining high levels of quality, safety, and efficiency in their operations. These certifications often include ISO standards, which indicate that the supplier has robust processes in place and undergoes regular audits to ensure compliance. This can give customers confidence in the supplier’s ability to deliver products that meet specific requirements.

Moreover, certifications can also play a crucial role in ensuring that the materials provided meet various regulatory standards. For example, in industries like construction or manufacturing, compliance with specific safety and environmental regulations is essential. A certified sheet metal supplier is more likely to provide materials that have been tested and verified for safety and reliability, reducing the risk of project delays or additional costs associated with non-compliance. Therefore, when evaluating potential sheet metal suppliers, it is wise to prioritize those who showcase relevant certifications, ensuring not only the quality of materials but also the overall integrity of your projects.

When searching for the best sheet metal supply services, understanding pricing structures is crucial to ensuring you get the best value for your investment. Different suppliers may offer a variety of pricing models, which can include per project pricing, bulk discounts, and tiered pricing depending on order size. It's essential to compare these models against the services provided; cheaper prices may sometimes reflect a lower quality of materials or limited service offerings.

Engaging with multiple suppliers for quotes can illuminate where discrepancies lie in pricing and can help identify competitive offerings. Always ask for a detailed breakdown of costs, which should include material, labor, delivery, and any additional fees. This transparency aids in making informed comparisons. Additionally, consider the supplier’s reputation and the quality of their service, as the lowest price may not necessarily yield the best overall value. Balancing cost with quality and service reliability will enable you to make a more strategic decision when selecting sheet metal supply services that meet your needs.

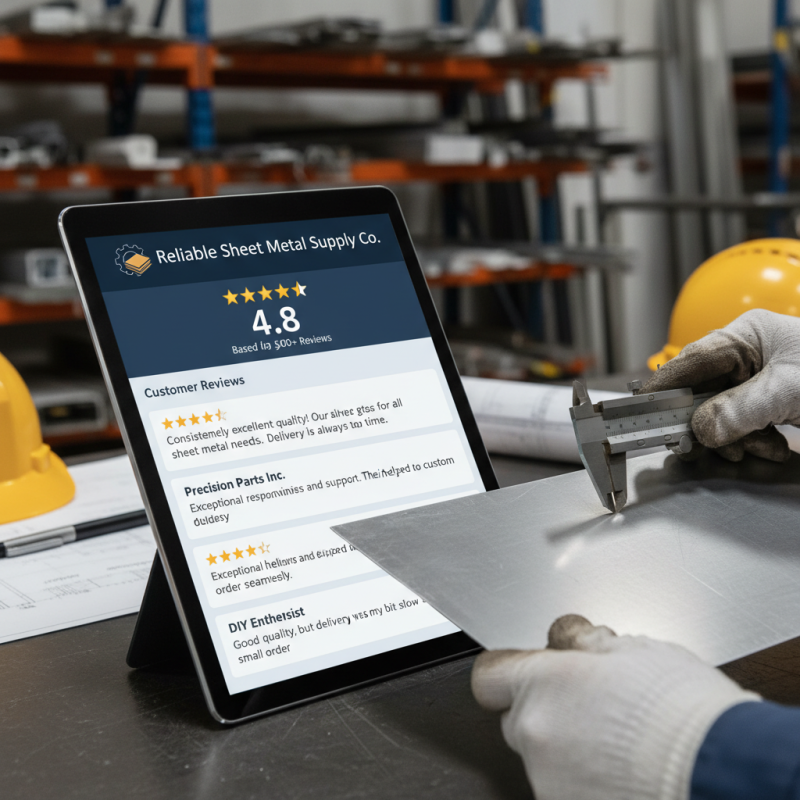

When searching for reliable sheet metal supply services, reading customer reviews can be an invaluable tool. Reviews offer insight into the experiences of previous clients, highlighting both the strengths and weaknesses of a provider's services. A high volume of positive feedback typically indicates a provider that excels in quality, customer service, and timely delivery. Pay attention to recurring themes in reviews; for instance, if multiple customers mention consistency in product quality or exceptional responsiveness, these are strong indicators of a trusted provider.

Conversely, it's essential to take note of negative reviews as well. If several customers report issues such as delayed shipments, poor communication, or subpar product quality, these red flags should steer you away from that particular service. Additionally, consider the context of the reviews—look for detailed accounts rather than vague praises or complaints. A provider that has addressed client concerns constructively is often more reliable and willing to improve. Ultimately, customer reviews serve as a crucial gauge for identifying sheet metal supply services that meet your quality and service standards.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close