As we look ahead to 2025, the landscape of sheet metal work is poised for significant transformation, driven by advancements in technology, sustainability initiatives, and evolving industry demands. Sheet metal work, a fundamental aspect of various sectors including construction, manufacturing, and HVAC, plays a critical role in developing efficient, lightweight, and durable solutions. The trends anticipated for 2025 are set to enhance productivity, streamline processes, and promote innovative applications, making it an exciting time for professionals within this field.

In this article, we will explore the top trends in sheet metal work that will shape the industry's future. From automation and digital fabrication to sustainable materials and eco-friendly practices, these trends not only reflect the technological advancements available but also respond to the broader movement towards sustainability in manufacturing. As the industry adapts to these changes, understanding and embracing these trends will be vital for professionals looking to stay competitive and relevant in the evolving market landscape of sheet metal work. Join us as we delve into the trends that will define the future of this essential craft.

In 2025, sheet metal fabrication is set to undergo significant transformations driven by emerging technologies. Advances in automation, particularly with robotic systems, are expected to enhance production efficiency and reduce labor costs. According to a report by the International Federation of Robotics, the global use of industrial robots in metalworking is projected to increase by 30% in the upcoming years, enabling manufacturers to achieve precise cutting and bending processes. This shift not only streamlines workflows but also minimizes waste, contributing to more sustainable practices within the industry.

Another trend to watch is the growing adoption of additive manufacturing techniques, which are proving invaluable for creating complex geometries that traditional methods struggle with. A study from the Metal Powder Industries Federation highlights that the metal additive manufacturing market is expected to reach $12.5 billion by 2026, underscoring its potential to revolutionize the design and fabrication of sheet metal components. This technology allows for on-demand production and customization, enabling businesses to respond swiftly to market changes.

Tip: To stay competitive in this evolving landscape, consider investing in training programs for your workforce. As automation and new fabrication technologies become more prevalent, equipping your team with the necessary skills will ensure they can effectively operate and maintain advanced systems. Additionally, continually assess your current practices to identify areas where technology could enhance efficiency and quality.

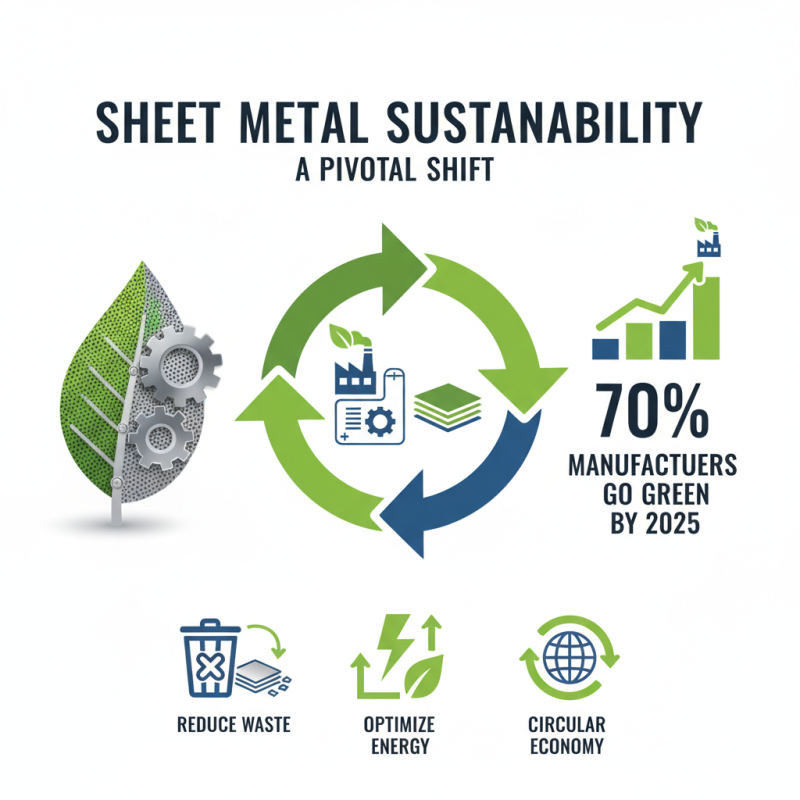

In the realm of sheet metal work, sustainability is no longer just a trend; it is a pivotal factor that shapes operational practices and product designs. According to a recent report by the International Sheet Metal Industry Association, approximately 70% of manufacturers are integrating sustainable practices into their production processes by 2025. This shift is driven by an increasing demand for eco-friendly materials and methods, as consumers and businesses alike prioritize environmental responsibility. This includes reducing waste through efficient use of scrap materials and optimizing energy consumption during production, leading to a more circular economy.

Additionally, advancements in technology are enhancing the sustainability of sheet metal work. Incorporating automated systems and IoT solutions helps companies monitor and refine their energy usage in real-time, significantly lowering their carbon footprints. Furthermore, innovations in metal recycling techniques enable the use of recycled materials without compromising quality, a crucial factor as studies show that recycling can reduce the carbon emissions associated with metal production by up to 40%. With these practices becoming mainstream, the industry is poised not only to meet regulatory standards but also to set new benchmarks in sustainable manufacturing, ensuring long-term viability and competitiveness in the market.

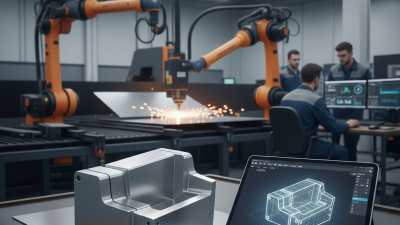

The sheet metal industry is on the brink of a revolutionary shift, driven predominantly by advancements in automation and robotics. According to a report from the International Federation of Robotics, the demand for industrial robots in metalworking is projected to grow by 25% annually over the next five years. This surge is largely attributed to the need for precision, speed, and efficiency in production processes. Automated systems are now capable of handling intricate tasks, such as laser cutting and welding, with remarkable accuracy, reducing both material waste and labor costs.

As companies look to enhance their operational capabilities, integrating robotics into the sheet metal workflow is no longer optional but essential. For instance, collaborative robots (cobots) are being employed alongside human workers to streamline tasks and optimize workflows. The flexibility these robots provide allows for rapid reconfiguration of production lines, which is pivotal in meeting the increasing demand for customized sheet metal products.

Tip: Invest in employee training programs to familiarize your workforce with new robotic systems and automation technologies. This not only enhances productivity but also helps in maintaining safety standards on the production floor.

Moreover, embracing digital tools such as simulation software can aid in planning and optimizing robotic operations. By leveraging data analytics, manufacturers can predict maintenance needs and minimize downtime, leading to more efficient use of resources and improved overall productivity.

Tip: Stay updated with industry reports and insights to better understand technological advancements and tailor your automation strategy accordingly.

In recent years, the sheet metal industry has seen a shift towards greater customization and design flexibility. As businesses strive to meet unique client demands, the ability to tailor products has become essential. This trend is reflected in the adoption of advanced technologies such as laser cutting and CNC machining, which allow for intricate designs and precise measurements. These innovations not only enhance aesthetics but also improve functionality, making it easier for manufacturers to deliver bespoke solutions.

Tips: When considering customization, think about the end-use of the product and the specific needs of your clients. Engaging in a dialogue with customers can yield valuable insights that inform your design process. Additionally, invest in software that supports rapid prototyping to streamline development and enhance your design capabilities.

Moreover, a flexible approach to design means that manufacturers can easily adapt to changing market demands. The rise of modular design in sheet metal products allows for easy assembly and disassembly, making it easier to cater to various applications. By incorporating this trend, businesses can reduce waste and improve efficiency while offering diverse products to their customers.

Tips: Always stay updated on emerging technologies and software in sheet metal design. Networking with other professionals can provide inspiration and foster collaborations that enhance your creative approaches.

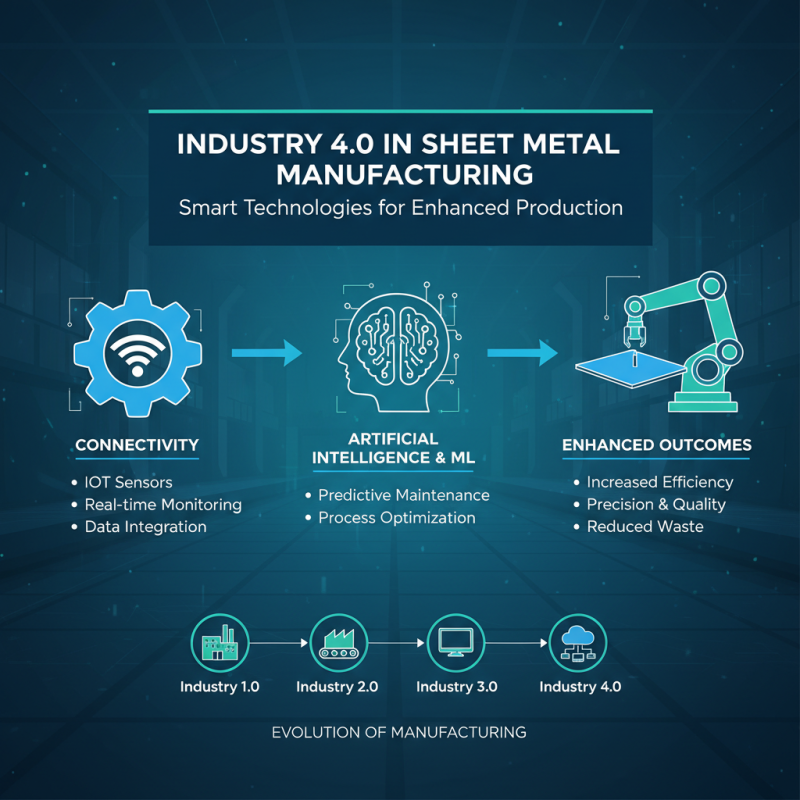

The advent of Industry 4.0 has revolutionized sheet metal manufacturing, introducing a suite of advanced technologies that enhance efficiency, precision, and flexibility. By integrating smart technologies such as the Internet of Things (IoT), artificial intelligence, and machine learning, manufacturers can achieve real-time monitoring of production processes. This connectivity allows for immediate adjustments to workflows, reducing waste and optimizing resource utilization. For instance, sensors can detect anomalies in machinery performance, enabling predictive maintenance that minimizes downtime and enhances productivity.

Moreover, Industry 4.0 facilitates greater customization in sheet metal fabrication. With advanced software and automated systems, manufacturers can easily adapt to changing customer demands and produce bespoke items with minimal lead time. The incorporation of digital twin technology enables manufacturers to create virtual models of production systems, allowing them to simulate and refine processes before implementing changes in the physical environment. As a result, companies can respond more swiftly to market trends while maintaining high standards of quality and efficiency in their sheet metal work.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close